|

Listen to this article

|

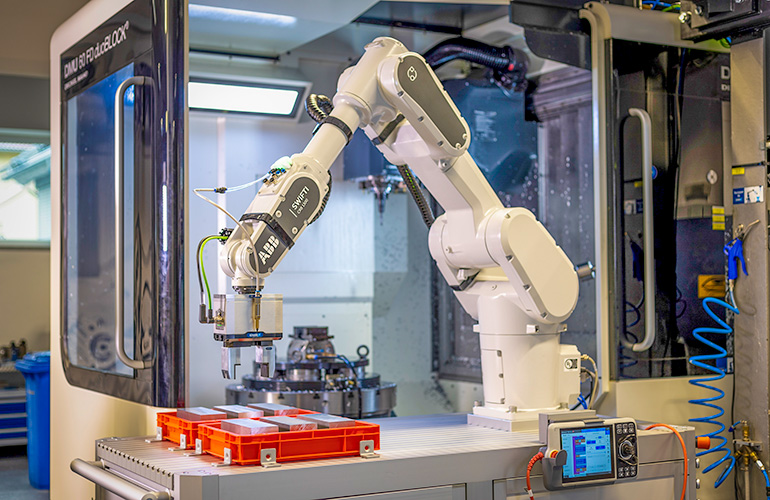

The ABB SWIFTI is an industrial-grade cobot with a reach up to 1300 mm. | Credit: ABB

ABB launched the SWIFTI CRB 1300 robot arm, which the company said bridges the gap between industrial and collaborative robots. With a payload capacity of up to 11 kg (24.3 lb), the SWIFTI CRB 1300 can be used in a variety of production and product handling applications – from machine tending and palletizing to pick-and-place and screwdriving.

The SWIFTI CRB 1300 uses a safety laser scanner integrated with ABB’s SafeMove collaborative safety software. The technologies enable safe collaboration without the space and cost associated with installing protective fencing or other physical barriers. If the laser scanner detects a worker within SWIFTI’s operating area, ABB’s SafeMove software will automatically slow the robot or stop it completely. As the worker moves away, movement will be restored, returning to full speed for full productivity only once the working area is clear.

As a further protective measure, a built-in interaction status light provides a visual indication of the cobot’s status when a worker is within the workspace area. The robot is powered by ABB’s OmniCore C90XT controller. Other features of the SWIFTI CRB 1300 include:

- Features ensure safe deployment alongside workers and ease of use for non-robotics specialists

- Available in three payload variants: 7 kg (15.4 lb), 10 kg (22 lb), 11 kg (24.3 lb)

- Reach between 900 mm (35.4″) to 1400 mm (55.1″)

- IP67 variant available for use in dusty, high moisture environments

- A top speed of 6.2 m/s (20.3 ft/sec)

- Repeatability of ±0.01 mm (±0.0004″)

ABB is offering the SWIFTI 1300 in three payload and reach combinations. | Credit: ABB

“Our customers are looking to robotic automation to make their processes more flexible, efficient and resilient, helping to counter labor shortages by enabling their employees to perform more value-added work,” said Andrea Cassoni, managing director for global general industry robotics at ABB. “The latest addition to our SWIFTI family is a highly accurate, high payload cobot that’s up to six times faster than other robots in its class. This means it can be used by both SMEs and large manufacturers looking for collaborative automated solutions to achieve new levels of flexibility and productivity.”

Users can set up the robot by either physically guiding it through a process (lead-through programming) or through ABB’s new Wizard Easy Programming software. Based on simple graphical blocks, Wizard Easy Programming makes programming accessible for non-specialists in robotics.

The SWIFTI CRB 1300 is part of a wider cobot portfolio covering payloads from 0.5kg to 11kg, with options including the YuMi single and dual-arm robots, the GoFa CRB 15000 and the SWIFTI CRB 1100 industrial collaborative robot for payloads up to 4kg.

ABB recently enhanced its RobotStudio robot programming and simulation software with cloud-enabled functionality. The new RobotStudio Cloud enables individuals and teams to collaborate in real-time on robot cell designs from anywhere in the world, on any device.

Tell Us What You Think!